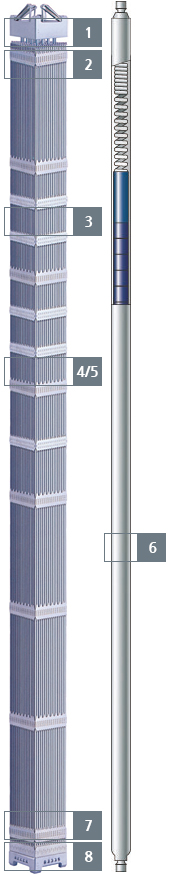

ACE7

- 1 Reconstitutable top nozzle

- 2 High bum up inconel grid

- 3 Intermediate flow mixing grid

- 4 Mixing vaned mid grid

- 5 I-type spring/High perfor-mance mixing vane

- 6 High bum up fuel rod

- 7 Protective

grid

- 8 Debris filtering bottom nozzle

ACE7 is an advanced nuclear fuel assembly for WH-type nuclear reactors. KEPCO NF launched the development of this international level fuel in 2001 and completed it in 2004; the achievement led us to commercial supply of ACE7 to 16×16 & 17×17 WH-type reactors in Korea starting from June 2008 after the in-pile evaluation of LTA (Lead Test Assembly).

ACE7 was developed from the conventional fuel supplied by Westinghouse Electric Company, and it has 7 improved performance factors:

- 1st, Improvement of neutron economy through optimized fuel rod diameter.

- 2nd, Improvement of grid-to-rod fretting wear resistance through I-shaped spring and widened dimple design.

- 3rd, Prevention of incomplete RCCA insertion through straight and tube-in-tube type guide thimble.

- 4th, Prevention of spring screw failure through integral clamp top nozzle.

- 5th, Improvement of debris filtering efficiency through protective grid and small-hole bottom nozzle.

- 6th, Achievement of high burn-up capability to more than 55,000MWD/MTU in comparison to the conventional fuel.

- 7th, Enhancement of thermal margin by more than 10%.