ATF, Accident Tolerant Fuel

Accident tolerant fuel (hereinafter, ATF) can significantly improve coping time even when the emergency cooling system of a nuclear power plant is lost compared to the current Zr-UO2 fuel system, and it is a nuclear fuel that can improve the safety of a nuclear power plant by greatly suppressing the amount of hydrogen generated.

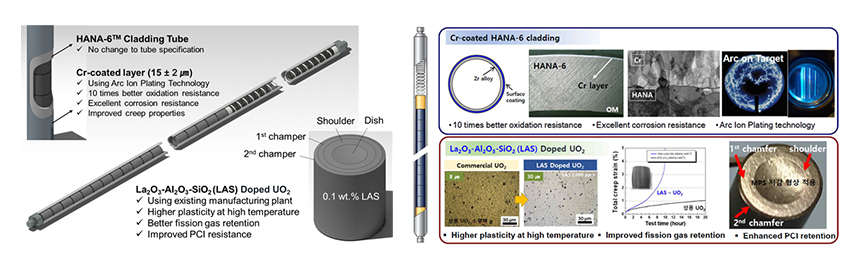

KEPCO Nuclear Fuel is making an effort to successfully develop and commercialize chromium coated zirconium cladding and advanced UO2 pellet. Cr-coated cladding can suppress cladding oxidation and hydrogen uptake under accident conditions, and the advanced UO2 pellet can relieve stress applied to the cladding by suppressing the release of fissile material and increasing deformation at high temperatures. Currently, the material development for ATF has been completed and is entering the stage of in-pile and demonstration tests.

Based on the excellent performance of ATF, not only the safety of nuclear power plants, but also economic effects can be expected through effective operation of nuclear power plants such as high burnup and load-following operation.

SIMON, SIMulation and MONitoring

SIMON is an operation support system developed with KEPCO NF’s proprietary technology. It is capable of identifying real-time operating condition and predicting future operating status of a nuclear reactor core using high order reactor analysis code system and high performance parallel computing techniques. Developing this kind of operation support system requires leading edge technologies. With the successful development of SIMON, KEPCO NF became the one of organizations that has developed its own operation support system.

Using the unique technology of SIMON, the operator will be able to accurately monitor the real-time status of a core, and the calculation accuracy and speed of core prediction will be maximized with special power shape matching method and automatic control rod search algorithm. With accurate core monitoring and prediction method, automatic planning and performing even wider range of possible operating strategies (e.g. long-term low power oepration, load follow operation) will be possible, as well as executing timely management of nuclear reactor power transient. In 2019, SIMON was domestically applied to the domestic WH type plants. Since then, many feedbacks has been successfully applied to further improve the quality of the system. The application of SIMON shows that there would be huge improvement of safety and utilization rate of NPPs, as well as considerable economic benefits.

High-intensity focused ultrasonic (HIFU) decontamination technology

High-intensity focused ultrasonic (HIFU) decontamination technology is a technology that safely and effectively decontaminates metal wastes of various shapes. KEPCO NF has developed HIFU technology for about two years from 2020 to treat complex metal waste that cannot be decontaminated with existing decontamination technology (melting process and sand blasting etc.). This technology can decontaminate low-level radioactive metal wastes to free release levels, especially in bent metal materials such as pipes and sticky surface contaminated wastes.

When HIFU technology is applied to the decontamination of the radiowaste in the nuclear industry, it is expected to have a significant reduction in waste and is a key decontamination technology that can be used in overseas nuclear markets in the long term.